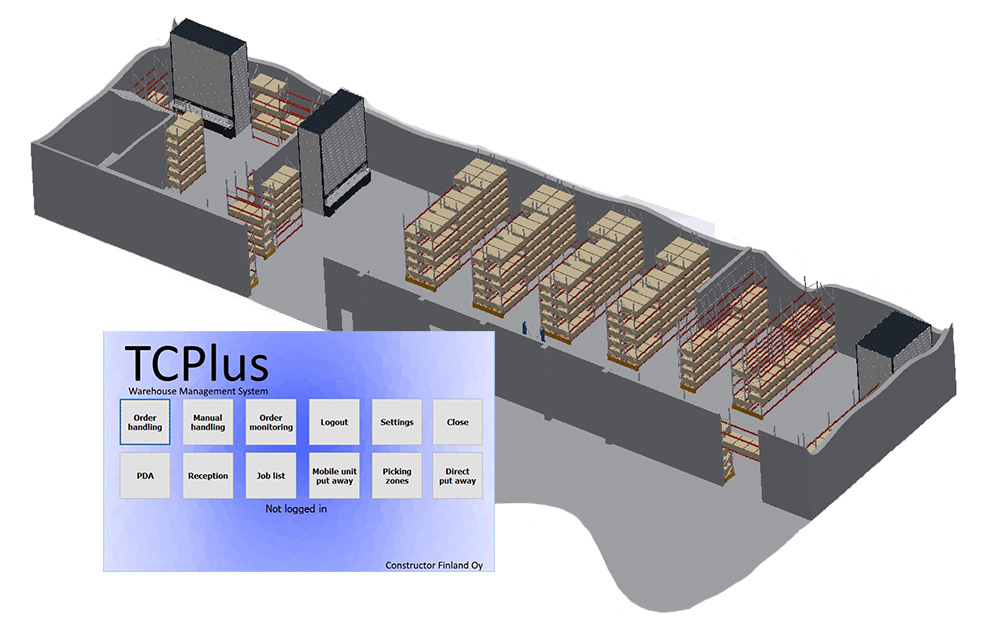

TCPlus can handle all basic storage operations as put away, picking, inventory, internal moving of items, check content on location and block specific storage locations.

TCPlus is easy to use and flexible system to create and manage storage systems. Picking, put away and inventory are effortless and quick by using an unique ID. Printing of various reports is possible from the system.

Receipt of goods

When the goods arrive, the system creates its unique identifier. The goods will go to the transit area from where it is moved to a storage location or a direct delivery area by reading the identifier.

Put away

In warehouse, each area can be divided into sections according to the rotational speed of the products. TCPLus always optimizes the location of the product and proposes a storage location, but you can also define it yourself if necessary. Put away is confirmed with an unique identifier or product code.

Picking

TCPlus creates a job list for picking. The same order can be picked from different areas at the same time by different users and the products are transferred to the collection area for shipping. Picking can be done at the point where the product is still in the transit area.

Inventory

Inventory of products can be made directly in TCPlus or according to inventory orders from ERP.

Handheld terminals (PDA)

- Easy to use and clear user interface in familiar Android environment

- Contains basic functions like picking, put away, inventory, internal moves, checking of storage location content, blocking of storage location

- Confirming of warehouse transactions are easy and quick by utilizing barcodes on storage locations and product batches

- Real time connection to main database in wireless network

TCPlus features and benefits

- Optimizes storage and picking efficiency

- Minimizes picking errors

- Keeps stock inventoried 24/7

- Keeps track on your stock movement

- Easy handling of product batches with unique identifier through the whole warehouse process

- Quick integration to all ERP systems and commissioning

- Easy to use – fast to learn

- Clear graphics that show all operations

- Moving items inside the warehouse

- Goods reporting

- Repetition diagrams for different warehouse areas and shelves

- Transaction history (who, what, when, where)

- Graphics monitoring of warehouse filling rate

- Monitoring of storage location types

- Monitoring of loading items

- Possibility of printing various labels during picking and put away

- FIFO, Floating storage locations, Fixed storage locations with or without quantity management

- Control data of a warehouse directly from the host system

- Support for controlling separate production batches of a single item per storage location concerned

- Several different languages option

- Control of user accounts and user rights

- Items weight control

- Items thumbnails or drawings

- Serial number connection to items

- Internal product-specific identifiers: pick labels, storage location labels, delivery address labels

- Receiving of goods to the transit area from where further processing for customer deliveries, storage locations and direct delivery area using an unique identifier

- Fast and easy-to-use tool for creating storage systems (warehouse layouts and addresses)

- MS SQL database and Terminal Server environment for work stations and PDAs