1. Tray

Trays are produced from galvanised sheet metal. All trays feature a steel-reinforced design and welded construction for added durability.

The TORNADO can operate in two different ways FTP and HOT. Both operation modes require different machine set-ups conserning the quantity of tray supports. Selecting the operating mode should be carried out during the purchasing phase.

FTP (Fixed Tray Position)

FTP solution uses the machines total storage capacity with fixed load height in the machine. Each tray has it’s own location and tray supports are installed based on that location. Tray is always returned to the same place. Machine control systems checks the load height each time when returning the tray.

When tray load height is changed, control system allows user to correct the new height.

FTP is the most efficient way of filling machines, we ”don’t store air”.

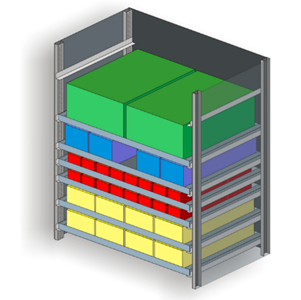

FTP, Fixed Tray Position

HOT (Height optimised tray)

HOT solution gives the machine the freedom of choice where to store the trays and the load height is dynamic. Tray supports are installed close to each other. No need to define load height in advance. The Tornado control measures the tray load height and brings tray to best possible location to minimise storage space loss. HOT operation mode requires always some empty space in order to funktion well. HOT is a good solution for example for production line, where product heights vary a lot.

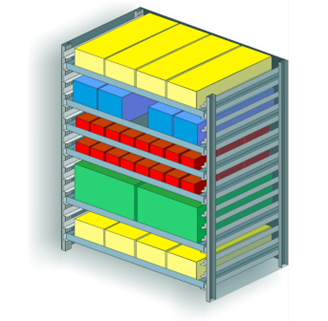

HOT, Height Optimised Tray

Big tray as standard

Tornado's Big Tray brings about 20-35% more products to pick per movement, which speeds up the picking by 20%. Big tray offers superior ergonomics and it can be divided into multiple sized compartments. Big tray means less movement and strain on the machine, and therefore also less need for maintenance. With the big tray the capacity of the Tornado increases and the required amount of machines decreases.

2. Belt

3. Height measurement / Safety light curtain

|

|

Height measurement device ensures optimum usage of space. Saftey light curtain stops the movement of the tray and therefore protects the operator. With saftey light curtain there is no need for inner door.

Click on the image or here to enlarge. |

4. Servo motor

5. Shaft sensor

6. Vertical motor

7. Cladding

Clear lines and clean surface makes operating more pleasant and gives the environment extensive comfort. The cladding can be tailored according to your brand or wished coloring.

Clear lines and clean surface makes operating more pleasant and gives the environment extensive comfort. The cladding can be tailored according to your brand or wished coloring.

Cladding and the corners are available in all RAL-colours. Standard cladding is delivered in white RAL 9002 and corners in gray RAL 7016. Cladding windows are also available as option; plexi glass window enables the curious ones to have a look inside the machine and follow tray movements.

8. WMS / TCPlus Software

TCPlus Warehouse Management Software optimises the picking route and guides picking from the most beneficial location. Fully integrated WMS software ensures perfect functioning with all ERP systems. Please find more information and facts about TCPlus here.

9. PC based control system

Tornado Vertical Lift Machine runs on an industrial PC enabling several benefits compared to the traditional PLC and logic-based storage machines.

Clear high-resolution graphics on a big color screen is delivered as a standard. You may choose the size and number of screens. Programs run on Windows operating system, the user interface is common to everyone today.

Tornado can easily be connected to a local area network and several machines can be connected together. Remote support is available to help the customer. This reduces the need to travel to site, and customer can be helped within minutes.

10. Lift system / table

Trays are moved up and down using load handling devices, LHD, on the left and the right side of the machine. The vertical movement is done by toothed belts, one on each side. The horizontal movement is done by chain.